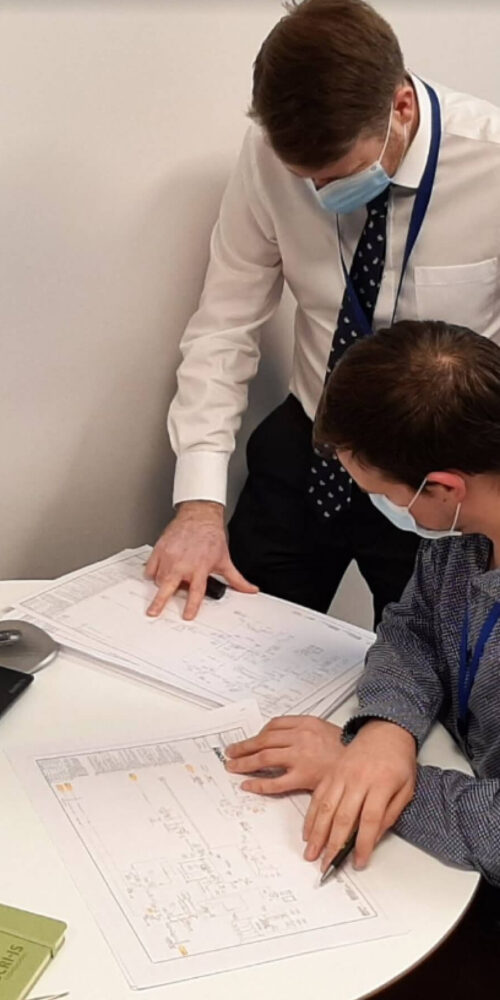

Our team follows rigid cGMP processes, to ensure that equipment is processed as our clients would expect. Our robust quality management system ensures that we follow strict procedures to ensure quality and consistency during the valve inspection and repair processes.

The SCRI-IS facility houses a custom-made, cleanroom-grade mechanical workshop, which is specifically tailored to the life sciences sector.

Our workshop is stocked with bespoke equipment which enables our team to carry out performance tests and simulate in-service conditions. Any possible valve overhaul or valve repair work can be done in our workshop, allowing us to refurbish equipment to the highest standards.

Testimonials

Linked Case Study

Check out our latest observations and insights into where it’s all going.