Machine downtime is a major disruption to production and can have a significant impact on manufacturing facilities. Downtime increases costs, leads to missed targets, and in the sectors of biotechnology, pharmaceutical and medical devices, can have detrimental ramifications on patients. At SCRI-IS, we have the solutions to mitigate against and prevent unnecessary machine downtime.

Who are we?

We are asset reliability specialists, and a trusted partner of biotechnology, pharmaceutical, and medical device manufacturers globally. The business was established in 2018 and is ISO 9001 certified.

We take our commitment to our clients seriously; it has even informed our name. SCRI-IS stands for Sustainability, Continuity, Reliability, Integrity and Intelligent Solutions. This forms the basis of our promise to clients.

We are an independent, Irish owned company and operate out of a state-of-the-art facility in central Dublin. Our facility contains several purpose-built laboratories that are specifically tailored to meet the needs of the life sciences sector. Our facility is unique in Ireland, and only a handful are in existence globally.

Our Solutions

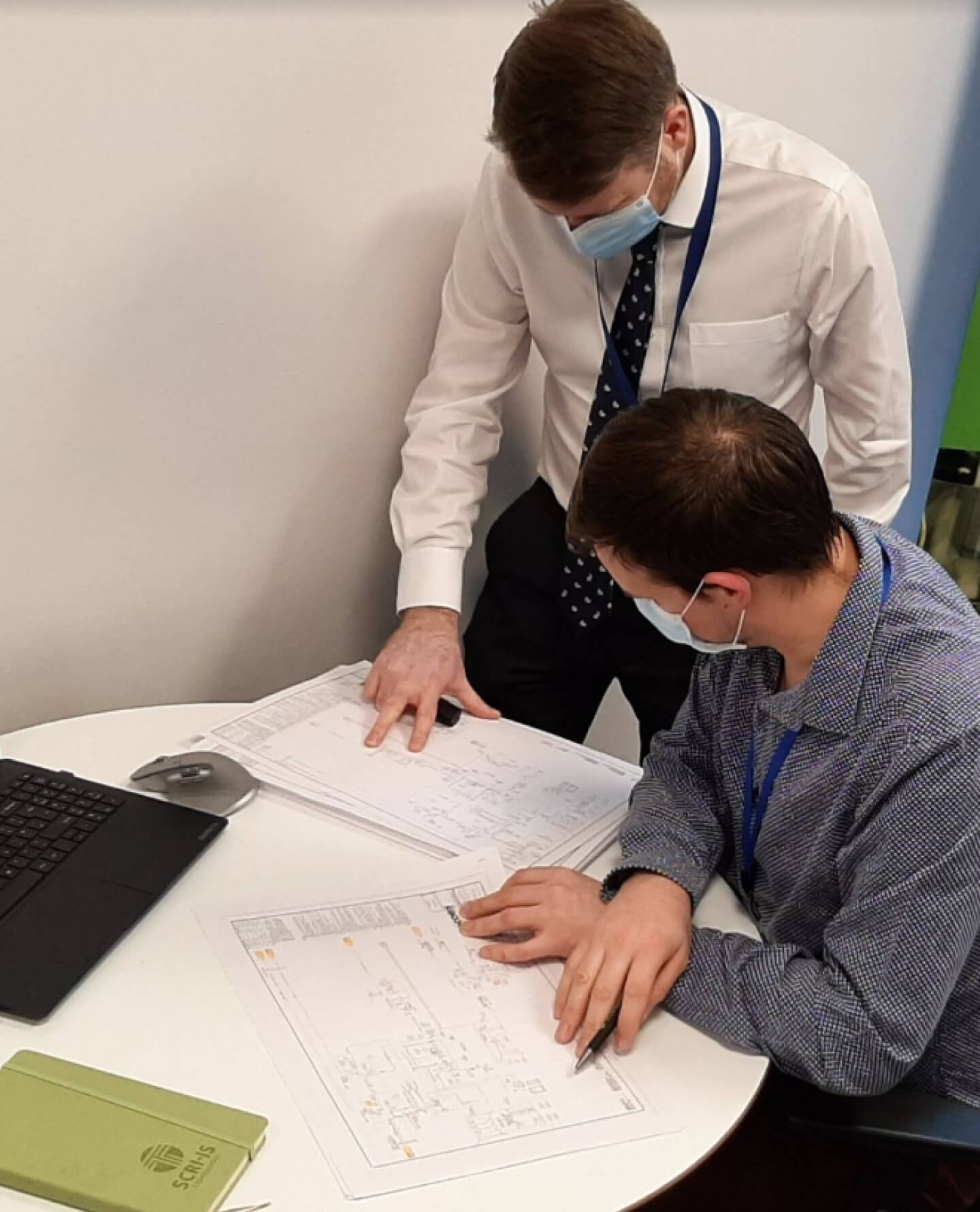

Using process system management, service, consultancy, life cycle testing, and advanced data analytics, we optimize equipment maintenance, preventing machine downtime and interruptions to production. Our specialty is in the biotechnology, pharmaceutical and medical devices sectors. Through a combination of industry expertise, procedural excellence, and state-of-the-art algorithms, SCRI-IS provides clients with bespoke packages which enable them to proactively select, manage, and verify unique solutions for their critical assets, maximize process integrity and minimize operational downtime. Our work minimizes risk for clients by maximizing system availability and production integrity.

Overall, our service combines expert knowledge, procedures, material science labs, bespoke analytics capabilities, and biotech industry experience, in order to provide clients with a turn-key package that enables them to reliably manage their critical assets on site.

Our services include:

- Preventive Maintenance Optimization (PMO)

- Elastomer Asset Management

- Valve Asset Management

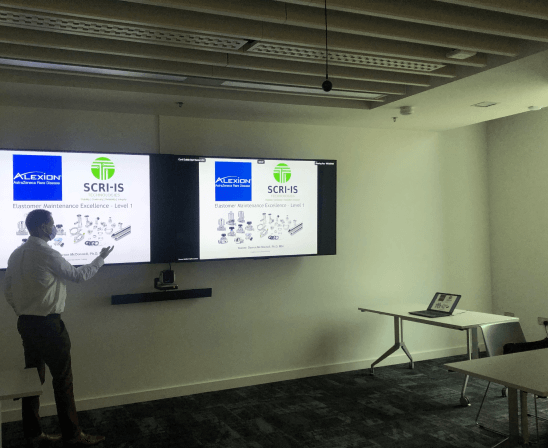

- Valve and Elastomer Training and Competence

- Accelerated Life Testing

- Elastomer and Valve Management Software and Risk Based Inspection

- Standard Operating Procedures (SOP) and Instructions

- Tooling and Inventory

- Remote Site Support

- On Site Support

Why We Do What We Do

SCRI-IS is aware of, and understands the challenges life sciences companies face, such as the increasing pressures to adopt new more dynamic manufacturing, maintenance, and digitalization strategies often within legacy facilities. The pressure to adapt the latest technological innovations is also matched by the need to ensure that output is not impacted in terms of quantity or quality. We work with our clients to enable the transition to, and use of, top quality process and equipment. Our clients who operate within the life sciences sector have a responsibility to ensure their products are of the highest quality, and that they have the capacity to match patient needs.

We recognize the need to move to a carbon neutral global economy and we believe that our work is very much to the fore in supporting the pharmaceutical and medical devices manufacturing sector to make that move. The sectors our clients operate in are energy intensive, and we help clients by optimizing their system reliability and reducing unnecessary downtime, which ultimately allows for production to take place at optimum energy efficiency. We also aid our clients in reducing the amount of plastic waste that is generated during the manufacturing process, reducing the amount of material that would otherwise end up in landfill.

Conclusion

We recognize the impact of machine downtime, for both industry and patient. We also understand the need to move towards a more sustainable method of manufacturing. We have the technology and expertise to help those within the biotechnology, pharmaceutical and medical devices sectors to make this transition.

Hi, this is a comment.

To delete a comment, just log in and view the post's comments. There you will have the option to edit or delete them.